There may be ongoing research and development to realize photovoltaic cells according to quantum dots, i.e. nanoscopic structures with Particular electronic Qualities. These could be produced from a wide array of inorganic semiconductors.

Regardless of the pointed out pros, the presently small market place share of amorphous silicon cells has recently declined as more development has been produced with crystalline cells.

The antireflection layer is usually an oxide of silicon, tantalum, or titanium that's shaped on the cell surface area by spin-coating or simply a vacuum deposition strategy.

The company caters to all markets — from personal residences to commercial Areas in both urban and rural areas.

Additionally, cell getting old might be accelerated at significant temperatures. On the other hand, the severity of every one of these results is very depending on the semiconductor substance applied together with other facts.

The resources accustomed to build the different layers of solar cells are essentially similar to People employed to produce the diodes and transistors of good-condition electronics and microelectronics (

A temperature and relative humidity probe that logs temperature and relative humidity details as time passes, supplying worthwhile environmental insights.

The short circuit current provides a sign with the copyright selection efficiency (for the provided cell spot and illumination level).

The basic structure of a solar cell is thoroughly intended. In this manner, it can maximise absorption and efficiently transform it into electrical energy. A standard solar cell is crafted from three most important levels. They can be the antireflection layer, energy-conversion layers, and electrical Get in touch with levels.

Photovoltaic cells crank out a voltage among their front and backsides. Each side should be electrically contacted. Not less than to the front aspect (and for bifacial cells, the backside also), this should be finished in such a way that The sunshine input is decreased as small as is possible. The typical system for standard silicon cells is to apply a grid cell solar system of great “finger” wires connected to much larger “bus bars” by screen printing a silver paste onto the front surface area.

The use of laser material processing is becoming important for low cost mass creation of solar cells. It truly is Utilized in various manufacturing steps which include the next:

This is certainly unlikely to happen each time a module is operated at its utmost electricity level, which has a rather decreased voltage.

Polycrystalline material is frequently produced in the form of square cast ingots, instead of cylindrical monocrystals. Wafers might be received from ingots by sawing, which unfortunately leads to a major reduction of fabric.

Troubles occur from toxicity (e.g. the compounds often find more contain direct) and restricted longevity, with adverse results from humidity and substantial temperatures. Study is ongoing to find less harmful compounds that are still economical and ideally more resilient.

Emilio Estevez Then & Now!

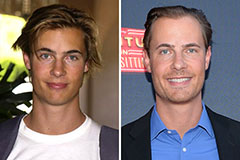

Emilio Estevez Then & Now! Erik von Detten Then & Now!

Erik von Detten Then & Now! Karyn Parsons Then & Now!

Karyn Parsons Then & Now! The Olsen Twins Then & Now!

The Olsen Twins Then & Now! Ricky Schroder Then & Now!

Ricky Schroder Then & Now!